Agitated Neusch Filter Cum Dryer (ANFD)

Slurry is charged through gravity or pump & vacuum is applied in bottom section through filtrate receiver.

Vacuum Tray Dryer

- Best suitable for sticky product.

- Suitable for very high vacuum application for solvent recover.

- Highly thermosensitive product upto 0.0001 mnhg.

Sparkler Filter

Liquid to be filtered is pumped into the filter shell and through opening on side plates. Filter media (paper / fabric) retains impurities allows crystal clear filtrate to flow through central channel formed by interlocking cups and to outlet of filter.

Rotary Vacuum Drum Filter (RVDF)

Best suitable for slurries with 20% to 40% solid (w/w). Cake can be washed satisfactorily. Oscilating agitator provided to keep the solids in suspension.

Fluid Bed Processor

- For uniform mixing various ingredients, granules & controlled drying in single unit.

- Coating of Granules by spraying.

- For spraying an active ingredient on carrier bed.

Continuous FBD With An Edge

“Turbulent Fluid Bed Dryer” is a novel design concept based on reliable “Turbulent Mixer System in conjunction with fluidized beds”.

Octagonal Vee Blender

- Double Cone Blender is designed to mix dry Powder & Granules to form homogeneous mixture.

Slant design ensures zero retention of powder on surface. - 100% discharge ensured due to double cone shape.

- Minimum particle size reduction due to absence of moving part.

Multi Column Distillation Plant

To produce sterile, pyrogen free steam conforming to IP/BP specification.

Rotocone Vacuum Dryer (RCVD)

- Batch type dryer

- Available with lump breaker

- Closed system / Automatic charging

- GMP units, ideal for pharmaceuticals, food products

Fluid Bed Dryer

The atmospheric air is taken through micron filter by induced Draft Fan. The clean air is heated either by Electric Heater/Stream Radiator.

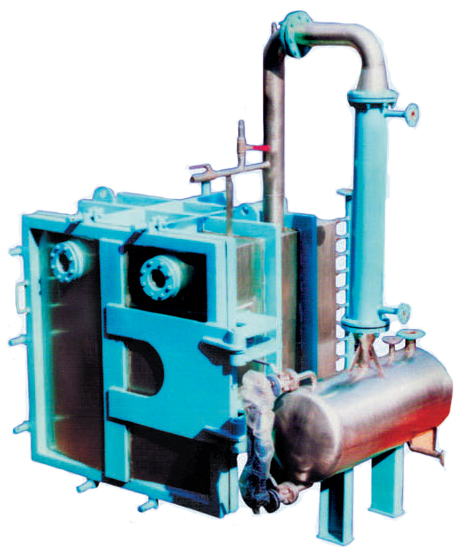

Pressure Leaf Filter

These Filters work on principle of Pressure & Precoating. The precoating is done with suitable Filter Aid (Hyflow, Superflow & Fuller Earth) by mixing in ratio 0.5% to 1% in Feed Slurry. This is pumped into the Vessel to form a Precoat on Filter Leaves.

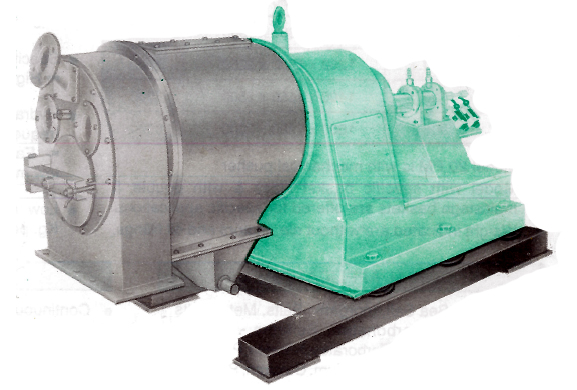

Centrifuge Pusher

The Pusher Centrifuge is basically used to seperate, slurries which are EASY TO FILTER, with an average crystal size of solids from 0.1mm (100 microns) to 10mm and fibre length of linter (for Fibrous materials) upto 30mm.

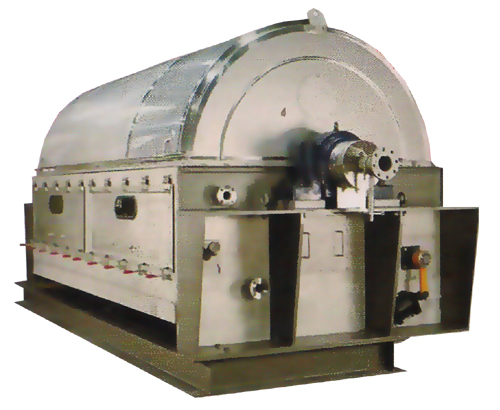

Drum Flaker

Special applications include single drum, double drum, twin drum and custom flaker.

Dry Heat Sterilizer

Vacuum Tray Dryer, Fluid Bed Dryer, Rotary Venuelathe Dryer, Rotocone Vacuum Dryer, Belt Dryer

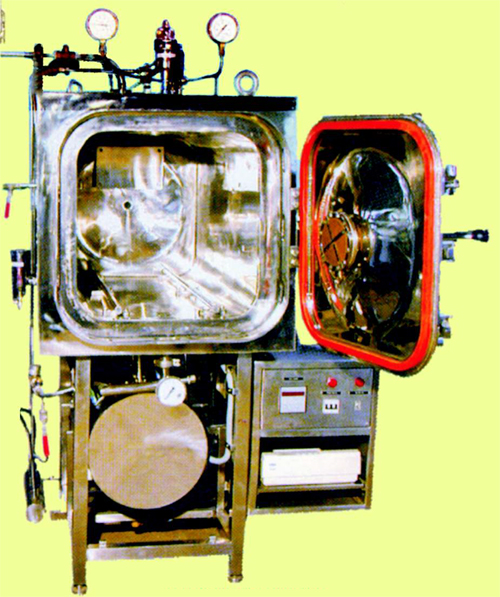

Autoclave - Steam Sterilizer

Batch Sterilizer

Dimpled jacket design ensures following:

Fast heat transfer

Equal temperature distribution

Additional strength to maintain chamber

10 to 15% less steam consumptionC-GMP Model

Chemicals Storage Stainless Tank

Stainless Steel for Wetted Parts

Stainless Steel OR Mild Steel for Non Wetted Parts Optional as per Client’s requirements